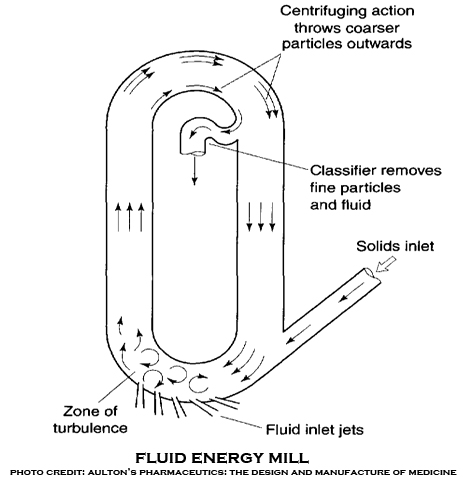

Fluidized Energy mill, also known as micronizer or jet mill is a type of mill that consists of a hollow toroid that has a diameter of 20-200 mm depending on the height of the loop which can be up to 2 m. It operates by particle impaction and attrition.

A fluid or milling gas, usually air or inert gas is injected as a high-pressure jet through nozzles at the bottom of the loop. The powder particles in the mill are accelerated to high velocity.

The kinetic energy of the air plus the turbulence created causes interparticle (particle-particle collision) and particle-wall contact resulting in particle size between 2 and 10 micrometers. The fluidized effect transports the particles to a classification zone where the size classifier retains the particles until sufficiently fine to be removed.  The particle size and share are determined by;

The particle size and share are determined by;

a. The speed of air/inert gas

b. Feed rate and size

c. The configuration of the mill

d. Design of the classifier

e. The position of the nozzle

f. The impact between the feed and air

Fluidized energy mill subclasses have no moving parts and primarily are distinguished from one another by the configuration and/or shape of their chambers, nozzles and classifiers. They include;

a. Tangential jet

b. Loop/oval

c. Opposed jet

d. Opposed jet with dynamic classifiers

e. Fluidized bed

f. Moving target

g. Fixed target

h. High-pressure homogenizers

Contents

a. Fluidized energy is used in milling thermolabile materials

b. It is the choice of mill when a higher degree of drug purity is required

c. Fluidized energy mill is used for the fine grinding of frits, Kaolin, Zircon, titanium, and calcium, alumina.

1. The machine has no moving parts and thus the tendency of contamination due to wear of parts is minimized.

2. The equipment is easily sterilized.

3. Small particle size (between 2 and 10) is usually obtained at the end of milling.

4. Thermolabile materials can be milled with little degradation since the heat produced by the process is nullified by the cooling effect of the expansion of the compressed gas.

1. Tendency of forming aggregates or agglomerates after milling.

2. Generation of amorphous content due to high energy impact.

3. Formation of ultra-fine particles