Tablet coating machine is the mechanical device that apply an essentially dry, thin layer of coating material to the surface of tablet dosage forms in order to confer specific benefits over uncoated variety. It is an equipment that coats the outer surface of tablet with a thin layer of coating material:

This article focuses on the working principles of tablet coating machines, the various types of tablet coating machines, and advantages of tablet coating machines.

Contents

The working principles of tablet coating machines are relatively simple. Tablet coating machines work by applying coating ingredients in the form of a solution to a group of tablets in a bed that may move horizontally or vertically. A concurrent flow of heated air facilitates evaporation of the solvents.

Several companies have developed their own coating machines to accommodate their coating processes. The several types tablet coating machines currently available in the market are based on these three principle types.

Standard coating pan consists of a circular metal pan mounted somewhat angularly on the stand. The pan is 8 to 60 inches (15 and 200 cm) in diameter and is rotated on its horizontal axis by a motor. The rotational movement of the pan causes the batch of tablets loaded into the pan to tumble and make multiple passes through the spray application zone.

Coating solution is applied to the rotating tablet bed by spraying in atomized form which can produce a faster and more even distribution of solution than simply introducing it as a liquid.

Heat air is directed into the pan and onto the tablet bed surface and is exhausted by means of the ducts positioned through the front of the pan.

Conventional coating pan

In order to achieve significant drying efficiency, a number of modifications were made to the design of the hot air handling equipment of standard coating pan. Typical examples of such modifications include the design of conventional coating pans with

Perforated coating pan consists of a perforated or partially perforated drum that is rotated on its horizontal axis in an enclosed housing. The coating solution is applied to the surface of the rotating bed of the tablets through spraying nozzles that are positioned inside the drum.

Perforated pans became popular when pharmaceutical manufacturers switched from organic solvent-based coatings to aqueous coatings. The switch was a natural response to the volatility of organic solvents; the high cost of explosion-proof installations, which became necessary in the 1980s to account for that volatility; and the introduction of the Clean Air Act and its amendments in the early 1990s.

Perforated coating pans come in various designs depending on the vendor, but the intention is to maximize the drying capability of the machine so as to minimize core penetration at high spray rates. They can be completely automated for both sugar coating and film coating processes. Examples of perforated coating pans include:

a. Accela-cota & Hi-coater systems

In these equipment the drying air is directed into the drum, passing through the tablet bed, and is exhausted through perforations in the drum.

b. Driacoater

In the Driacoater, the drying air is introduced through the hollow perforated ribs located on the inside periphery of the drum. As the coating pan rotates the rib dip into the tablet bed and drying air passes up through and fluidizes the tablet bed exhausting through the back of the pan.

c. Glatt coater

Glatt coater (Glatt perforated coating pans) design uses fully perforated drums – a feature which combines maximum spray rates and extremely short process times. In a Glatt coater, the drying air can be directed from the inside the drum through the tablet bed and out an exhaust duct; alternatively with an optional split chamber plenum, drying air can be directed in the reverse manner up through the drum perforations for partial fluidization of the tablet bed. Several airflow configurations are possible.

Various designs of perforated pans

3. Fluidized bed or air suspension systems

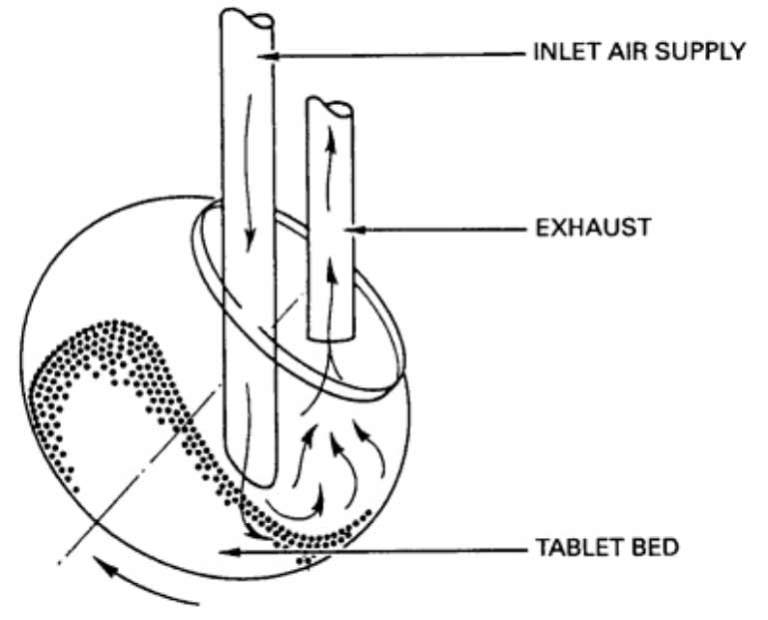

Fluidized-bed coating equipment or air suspension coaters are highly efficient coating systems in which the coating solution is sprayed on to tablets (or granules) that have been suspended in a columnar chamber by a positive (warmed) airflow. The airflow is controlled so that more air enters the center of the column, causing the tablet to rise in the center. The tablets in the center move upwards in the airflow and fall outwards and downwards to the chamber wall, at which stage the process is continuously repeated from the bottom part of the column. Coating solutions are continuously applied from the spray nozzles located at the bottom of the chamber or sprayed onto the top of the cascading tablet bed by nozzles located in the upper region of the chamber.

Tablet cores that are friable and prone to chipping and edge abrasion may be difficult to coat even under the optimum conditions in the fluidized bed systems, owing to the relatively rough tablet to tablet impact and tablet chamber contact.

Schematic diagrams for three basic processes used for fluid-bed film coating

There are basically two types of spray-atomization systems used to apply a finely divided spray coating solutions or suspensions onto the tablets.

The advantages of tablet coating machines will be listed with respect to the three principal types